Sinowa is a well-known Rock Wool Panel Manufacturing Machine Supplier From China, Dedicated to the research and development of high-end & high-efficiency rock wool panel machine, Sinowa is comprehensively taking the leading position in terms of efficiency, automation control level, HMI, environment protection and energy consumption, with subversive designs made in some critical technological fields to procure exceptional cost performance and customer-friendly experience for the entire rock wool panel machine.

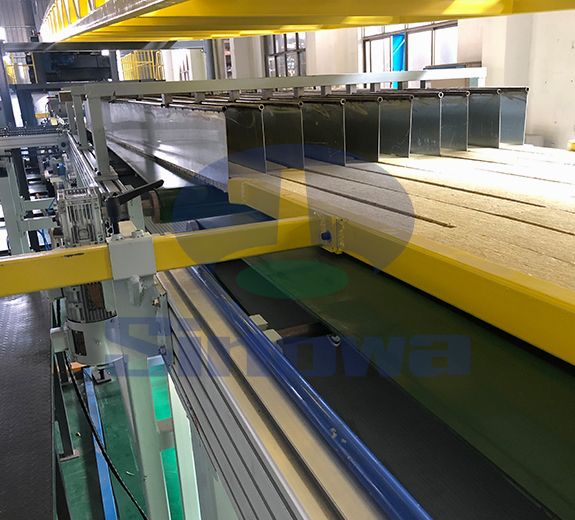

The adoption of system integration technology and bus control technology accomplishes the full automatization of integrated and coordinated control of the entire sandwich panel line with accessible remote interactive communication.

Based on the continuous technological pursuit, the rock wool panel machine developed by Sinowa provides you with high-efficiency industrial value. Based on China's cost advantage and our hard-working technology concept, our mineral wool sandwich panel line has a world-leading price-performance advantage. Continuous Rockwool Sandwich Panel Production Line can meet a variety of production needs of customers.The whole line design concept of modularization enables all our components to be integrated and combined at will.

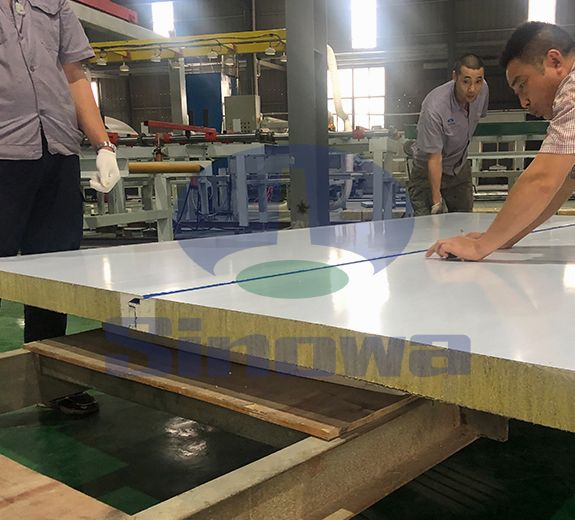

Our rock wool panel machine can easily automate the production of roof sandwich panel, wall sandwich panel, cold storage sandwich panel and other products by different combination and configuration selection and siple switching. The inner core layer can be polyrethane or rock wool, glass wool, an so on.

The rock wool panel machine has high adaptability, which may produce various sandwich panel of the PU, PIR and rock wool systems.

We may design various products according to the customer’s requirements, including various configurations, so as to meet their demands with flexible price system.

Highly integrated and linked control system centralizes all control points at the main central center, achieving parameter linkage, fault self-diagnosis controlled by the whole line and shipping distance control.

High-level automatic control system also saves the manpower and reduces the manpower loss for customers.

Concentrated system control is fully realized in the practice of concentrated process control so that the control system of all the movements of the parts in the line is integrated in one process control console with accessible remote communication to elevate the automation and reduce the allocated number of personnel for the assembly line.

The main engine with modularized design achieves the precision operation of the rock wool panel machine, stable and reliable quality, less part and maintenance loss.

The whole pu sandwich panel line is strictly modularized in design to ensure the greatest probability for the parts to be interchangeable, making it the most cost- and energy-saving. No joining made manually, all the key processes of the parts are completed in the machining center. As soon as the parts are inspected and warehoused, they enter into the assembly process. The modularized assembly can not only greatly increase the production efficiency but, most importantly, realize quick delivery as well. It elevates the reliability of product quality to a totally new level and minimizes the influence from human factors.

The whole rock wool panel machine has over 40 innovative inventions, making our products have lots of unique features and the comprehensive performance of our production line leading in the industry.

The precision servo hoisting mechanism employed by the main engine without hydraulic system makes the board thickness control flexible and the customer may conveniently change or adjust the board thickness. There will be not such troubles as hydraulic system adjustment, leakage, maintenance, etc.

High-level energy saving and protection design makes the whole rock wool panel machine possible to produce around the clock throughout the year and the customer will save huge budget. In addition, the isolated heat preservation room is constructed for warming the environment. The energy saving and protection design of our rock wool panel machine may guarantee that the customer’s rock wool sandwich panel line may be freely heated and produce in the main time to save more costs for customers.

The high-power low-consumption design quickens the reaction of the rock wool panel machine while energy consumption is kept low.

With the brand-new, fully sealed inner insulation design, the energy consumption is controlled at the minimum level to achieve the design objective of less than an hour for the insulation system to be activated from the room temperature above 5℃ to the production process temperature.

The energy consumption is only 40% that of those similar products.

| PRODUCTION TYPE | PU | PIR | PHENOLIC | |||

|---|---|---|---|---|---|---|

| PRODUCTION USE | INSULATION PANEL | DOCORATIVE PANEL | ||||

| SURFACE OF SHEET | ALUMINUM FOIL | NON-WOVEN FABRIC | PAPER | NAKED | ||

| PRODUCT THICKNESS | 10m--- 200mm | |||||

| PRODUCTION SPEED | 3.0m---25m |

|---|---|

| FOAMING METHOD | TWO OR MULTI COMPONENTS FOAMING |

| FOAMING AGENT | PENTANE OR 141B |

| LENGTH OF LINE | 45m—100m CUSTOMER OPTIONAL |

Sinowa is a well-known manufacturer and technical service provider of high-end polyurethane insulation board production lines and various high-performance cold roll forming machine in China. Our main products include polyurethane double-sided color steel sandwich panel production line, polyurethane and phenolic soft facing insulation panel production line and high-efficiency roll forming machines.

Sinowa has invested outstanding efforts in rock wool panel manufacturing machine, This is why our products are more efficiency, quality, automatic control technology, environmental protection, energy consumption indicators and the appearance and safety protection are comprehensively leading, Some subversive design changes in many major technical points,these major innovations make our products excellent in price/performance and user experience.

Sinowa is committed to the development and manufacturing of high-end and high-efficiency rock wool panel manufacturing machine. Our sandwich panel production lines are leading the way in efficiency, automatic control, human-computer interaction, environmental protection and energy consumption. Using system integration and bus control technology, it realizes the automatic integrated linkage control of the entire production line, and can achieve remote interactive communication, which has the world-class level and a comprehensive leading high-performance production line in the market.

?Rock Wool Panel Manufacturing Machine? Post Date:2023/9/19

URL: http://m.shionoe.com/en/blog/rock-wool-panel-manufacturing-machine.html

Tags: Automatic Rock Wool Panel Machines , Rock Wool Panel Machine ,